Testing the durability of Mars lander legs by engineers

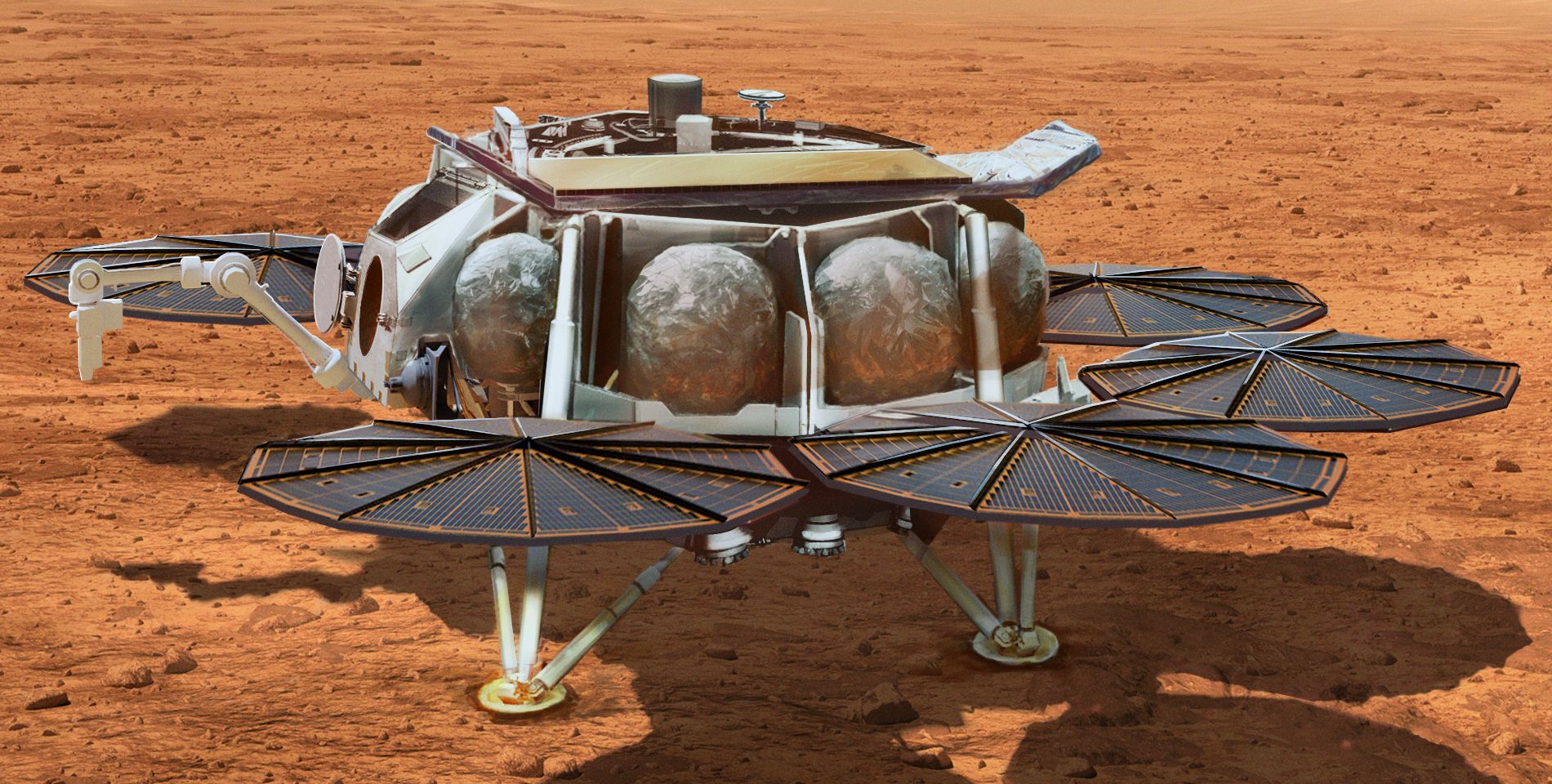

Engineers at NASA’s Jet Propulsion Laboratory in Southern California are putting the legs and footpads of the Sample Retrieval Lander to the test. This lander is being designed to bring rock core samples collected by NASA’s Perseverance rover back to Earth as part of the Mars Sample Return campaign. The lander will be the largest spacecraft to ever land on Mars, weighing up to 5,016 pounds (2,275 kilograms). The legs of the lander are crucial for absorbing the impact of touchdown and ensuring a successful landing.

NASA is drawing on its decades of experience with Mars landings to inform the design of the Sample Retrieval Lander. The lander will rely on next-generation parachutes and 12 rocket engines to slow its descent to Mars. In addition, the legs will play a vital role in absorbing the impact of landing. The lander will also carry a rocket that will launch the rock core samples collected by Perseverance to an awaiting orbiter. A robotic arm provided by the European Space Agency (ESA) will load the sample tubes into the rocket. The lander may also carry mini-helicopters to serve as backups for retrieving tubes deposited in a sample depot.

To understand how energy is absorbed during landing, engineers at JPL conducted drop tests earlier this year. These tests involved dropping a scaled-down model of the lander onto a hard floor and slamming a full-size footpad into simulated Martian soil. The observations from these tests will inform the design of the lander and subsequent tests. The engineers have already made significant improvements to the initial design based on their findings.

One particular challenge the team has considered is what would happen if the lander touched down at an angle and “stubbed a toe” on a rock. To simulate this scenario, they dangled a prototype from a pendulum and sent it to the ground at an angle. They discovered a wobble in one of the leg’s main struts, which would be even more pronounced in a larger lander. To address this, stronger flight struts will be designed to handle the forces.

The team has also tested the lander’s “load limiters,” which are steel rods that connect its chassis to its legs. These rods bend during touchdown, absorbing some of the impact. The limiters used on previous landers like InSight are larger on this prototype and will be even larger on the final design.

The footpads of the lander have also undergone testing in a box filled with 10,000 pounds (4,536 kilograms) of powdery, Mars-like soil. The footpad attaches to an assembly with nearly a half-ton of iron weight plates. The impact of the footpad plunging into the soil was powerful enough to shake the walls of the testing facility. High-speed cameras captured how energy radiated out from the pad. The team aims to ensure that the lander’s feet do not sink too far into the surface and that it remains stable for rocket lift-off.

The testing process for the footpads is time-consuming as the soil bed needs to be rebuilt and compressed after each test to mimic conditions on Mars accurately. This process is repeated four times a month to ensure consistency and gather valuable data on how the footpad interacts with the soil.

Overall, these tests and observations are crucial for refining the design of the Sample Retrieval Lander and ensuring a successful mission to bring rock core samples from Mars back to Earth for further study. The engineers at NASA’s Jet Propulsion Laboratory continue to work tirelessly to overcome various challenges and ensure that the lander’s legs and footpads can withstand the demanding conditions of landing on Mars.